Operating the Mill

This is from the 2009 edition which is currently being revised.

PRACTICE TO BE STRICTLY FOLLOWED WHEN OPERATING THE WINDMILL

Only qualified persons are permitted to run the mill, or operate within the mill.

There are three levels of operatives :-

Mill Guides – persons who are trained to conduct guided tours of the mill.

Assistant Millers – persons who have had training in the use of the brake, and are able to set the sails and take responsibility for the idle running of the mill.

Senior Millers – persons who have had training in the whole operation of the mill and able to carry out the process of milling and take the responsibility for the correct procedures being followed as laid down in this operating manual.

NB. Although not mandatory, even mill guides should be trained to operate the brake.

The sweeps should always be left facing the wind in the St. Andrews cross position when not in use, with the sweep number of the corresponding week in the month at the 7.00 O’clock position. If the wind is very strong it may be necessary to tie the mill into the wind.

When the Mill is closed down the brake is applied, the brake lever is pegged and wedged. Timbers inserted through the clasp arms of the brake wheel and onto the sprattle beam will prevent inadvertent rotation of the sails. These timbers or chocks must be removed before running the mill.

Before Operating the Windmill

Before the windmill may be operated the miller-in-charge, or lead-guide who wishes to only operate the sails, must ensure that the site will be safe for operations. The "Closed to the Public" sign should be hung over the gate and if there are insufficient people to have one in the field to ensure no-one unexpectedly enters the field then the gate should be padlocked.

The roundhouse door nearest to the sails should be locked.

The mesh netting should be installed from beside the roundhouse door, in a semi-circle around the sails, supported by the metal stanchions that are designed to slot into holes in concrete pads set regularly into the ground around the mill for this purpose. The remainder of the roll of netting can be propped against the roundhouse, but the free end will need to have a stanchion hammered into the ground near the roundhouse door.

All volunteers on site should be informed that the sails will be operating and warned not to go inside the area fenced off by the mesh netting.

| High Salvington Mill Technical Training Record | |||||

| Name of Trainee | |||||

| No | Task | Date completed | Trainer Signature | Trainee Signature | |

| MILL GUIDES | |||||

| 1 | Turning the mill into the wind. | ||||

| 4 | Operating the brake. | ||||

| ASSISTANT MILLERS | |||||

| 1 | Turning the mill into the wind. | ||||

| 4 | Operating the brake. | ||||

| 5 | Fitting and setting the sailcloth’s. | ||||

| 7 | Setting and stowing the spring shutters. | ||||

| 8 | Running the sails under guidance. | ||||

| 9 | Responsible for the mill & running sails on open days. | ||||

| 3 | Turning the sails weekly. | ||||

| 2 | Securing the mill for stormy weather. | ||||

| SENIOR MILLERS | |||||

| 1 | Turning the mill into the wind. | ||||

| 4 | Operating the brake. | ||||

| 5 | Fitting and setting the sailcloth’s. | ||||

| 7 | Setting and stowing the spring shutters. | ||||

| 10 | Responsible for the mill & running sails when grinding. | ||||

| 3 | Turning the sails weekly. | ||||

| 2 | Securing the mill for stormy weather. | ||||

| MILL MAINTENANCE | |||||

| 6 | Replacing & whipping ropes. | ||||

| 11 | Greasing collar also neck & tail bearings. | ||||

| 12 | Lifting the runner stone. | ||||

| 13 | Cleaning stones & chutes etc. | ||||

| 14 | Greasing & shimming bed stone bearing & hackle plate. | ||||

| 15 | Checking wedges & sag irons. | ||||

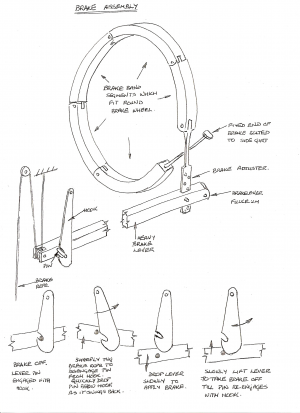

OPERATION OF THE BRAKE

Operating the brake using the brake rope takes a little practice, but should be learned by everyone. Understanding the mechanism of the brake lever and the swinging hook will help in the use of the brake rope. The application of the brake should be done gradually, as sudden sharp braking can result in a broken sail stock.

TO RELEASE THE BRAKE

- Remove the timbers or chocks from the brake wheel.

- Remove the peg and wedge from the brake lever.

- Check that the hopper cloth cover is well clear of the brake wheel or removed.

- Ensure the wire machine is out of gear and the lever is securely tied to prevent accidental engagement of the auxiliary shaft to the wire machine.

- Ensure that both stone nuts are out of gear.

- Ensure that there are no obstructions to the brake and tail wheels.

- Ensure the brake rope is free from obstruction through the “Pop hole” to outside.

- Ensure the area outside in front of the sweeps is clear of people and obstructions, and the netting is in place if required.

- Release the brake by pulling the brake rope to its maximum, then gently release tension on the rope. The rope will stay almost in that position as the swinging lever hook engages with the pin on the brake lever, holding the brake lever in the “Off” position.

- Coil and leave the rope tidily on the ground where it is not an obstacle.

TO APPLY THE BRAKE

- Give the rope a sharp tug and quickly let out a little rope. This will free the swinging lever hook from the brake lever pin, and allow the brake lever to drop below the hook. Slowly let out the rest of the rope which will gradually apply the brake as the heavy brake lever is lowered inside the mill.

NB. The rope must be released slowly in order that the brake is applied smoothly otherwise damage to the sails may occur.

SETTING THE SAILS

At least one Senior or two Assistant Millers together with another person must be on site whenever the sails are set.

The climber must ensure their own safety. Suitable footwear should be worn. Gloves, hard hat and ropes are available.

The common sails should always be set before the shuttered sails, as there is less sail area to turn the sails in a sudden gust of wind when climbing them, than if the spring-shuttered sails were set first.

If the wind is very strong, it is better to turn the mill out of the wind beforehand.

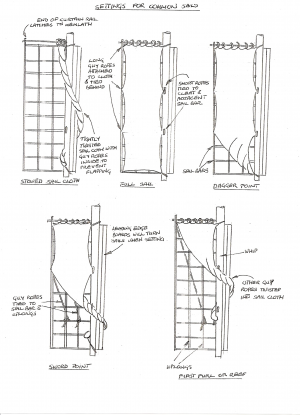

SETTING THE COMMON SAILS

- A sweep must be brought round manually into a vertical position and the brake applied. The brake man should shout “BRAKE ON” once the brake has been set. The climber should confirm they have heard this by responding.

- The sailcloth is untied and unfurled from around the leading edge of the sail.

- One person should hold the bottom of the sailcloth while the climber is aloft to prevent a sudden gust flapping the cloth and endangering the climber. NB. In windy conditions a sudden gust of wind can sometimes turn the sails, even with the brake on. A separate person should always hold the sail while the climber is aloft to tie the ropes.

- The short pairs of ropes on the right hand side of the sail cloth are secured to the two cleats on the whip NB. Each rope should first go round the adjacent sail bar, to prevent the sail becoming unfastened in any back wind. To minimise the risk of falling when securing the ropes to the cleats, the climber should use the sail as a ladder. The sail should be ascended adjacent to the whip, with one leg hooked over the sail bar above for safety, thus freeing both hands to tie the ropes.

- Once the climber has secured the sail to the cleats and is back on the ground, the sailcloth can be spread by pulling the top guy rope sideways away from the stock.

- The three guy ropes are made taught and secured around a sail bar and hemlath at the back of the sail frame using an approved knot.

- The sailcloth is pulled down tightly round the bottom of the sweep and tied securely at the bottom corners of the sail frame and whip. Should the wind be very strong, one or both sails can be reefed to one or other trailing edge rope positions, the reefed part of the sail being twisted anticlockwise and tied to a sail-bar. NB By twisting the sail anti-clockwise, the rolled part of the sail will be behind and present a flatter air surface to the wind. This gives four sail configurations, namely :- First furl or reef, Sword point, Dagger point and Full sail.

TO “UNSET” THE SAILS

these procedures are reversed :-

The common sails must be “Unset” after the spring shutter sails.

- Each sweep must be brought round manually into a vertical position and the brake applied

- When the sail-cloths are stowed, the three trailing edge ropes are folded into the sail-cloth, which is tightly twisted and threaded round the whip and through the sail (to prevent flapping), the end ropes being secured to a low sail-bar and bottom of the whip.

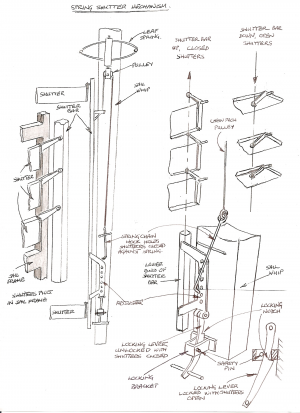

SETTING THE SPRING SHUTTER SAILS

The spring shutter sails must be set after the common sails.

These sails resemble the slats of a Venetian blind. The shutters are held closed against the action of a leaf-spring situated at the top of the sail. Should the wind become too strong, the pressure on the boards overcomes the spring pressure, allowing the boards to open and spill the wind. The spring pressure can be varied for different wind conditions, by re-positioning the spring chain hook into one of the holes in the adjuster.

A separate locking lever at the bottom of the sail will also allow the boards to be locked in the open condition and will not close should the mill be tail-winded. The boards should be locked open at all times when the mill is not in use.

When setting the sail, the lever is pulled forward into the unlocked position and the boards held closed using the spring chain hook.

The spring chain hook should always be engaged in a hole on the adjuster whether the sails are in use or not.

- A sweep must be brought round manually into a vertical position and the brake applied.

- Remove the safety pin from the locking lever bracket which holds the locking lever in place.

- Release the spring chain hook from the adjuster.

- Pull out the locking lever to release the tension on the leaf spring and free the shutters from their “locked open” position. (NB. Take care to hold the cross bar by its ends to prevent trapping fingers as the spring loses tension. )

- Replace the safety pin into the bracket.

- The spring can now be re-tensioned to hold the shutters closed, by placing the hook on the spring chain into one of the adjuster holes. Spring tension can be increased using a lower hole, so that the shutters open in a higher wind or vice versa.

TO “UNSET” THE SPRING SHUTTER SAILS

these procedures are reversed :-

The spring shutter sails must be “Unset” before the common sails.

- A sweep must be brought round manually into a vertical position and the brake applied.

- Remove the safety pin from the tension lever bracket.

- Release the spring chain hook from the adjuster hole.

- Pull down the locking lever (attached to the shutter bar) and latch a notch on the locking lever onto the locking lever bracket.

- Replace the safety pin in the bracket so that the locking lever cannot become dislodged, leaving the sails safely secured with the shutters locked open to allow the wind to blow through them.

- Safely stow the chain hook by and pulling it down (against the spring tension) into a hole in the adjuster.

.

SAILS ONLY TURNING

At least one Senior Miller with another person must be on site whenever the sails are set.

If visitors are on site the Senior Miller must decide whether to erect a safety barrier around the sail area.

No visitors allowed on the stone floor whilst sweeps are turning – except at the discretion of the Senior Miller.

Note – If the sails are being turned whilst no visitors are on site for maintenance etc. the “Closed to the Public” sign should be displayed on the gate.

- The senior miller must be aware of weather conditions and must direct the duties of others accordingly in setting the sails and running the mill.

- Check wind direction.

- Check the electric cables in the roundhouse if turning the mill.

- Release the talthur, raise the steps, and turn the mill into the wind.

- Lower the steps.

- Unchock the brake wheel.

- Unpeg the brake lever putting the brake rope through the side hatch.

- CHECK :-

The stone nuts are out of gear.

Brake and tail wheels are clear of obstructions

Hopper covers are removed or will not foul the brake wheel.

Wire machine is out of gear.

THE MILLING OPERATION

At least two Senior Millers must be on site when milling is taking place with a minimum of three persons on duty.

A Senior Miller must be nominated for the day or session and assume overall responsibility for the milling operation.

Before the commencement of milling the following must be checked :-

GENERAL

- Sufficient grain for the anticipated milling is available on the stone floor, and the hopper is full and the grain flows freely from hopper to shoe.

- Clean bins and sacks are available on the spout floor.

- The spouts to be used are clean and free of any moth etc.

- Attach a sack under the spout.

- Check the governor drive belt is in place if required.

- Jobs and duties are allocated to the staff available.

- Check the location of electric cables in the roundhouse if turning the mill.

- Ensure the mill is facing into the wind for full power. NB In strong wind the sails may have been set with the mill out of the wind.

- Ensure that no person is in range of the sails.

The “Closed to the Public” sign should be displayed on the gate, and the gate locked.

INSIDE THE MILL

Stone Floor

- Add grease to the grease wedge and replace in the bed stone bearing.

- Ensure that there is oil in the footstep bearing of the stone spindle.

- Grease the glut box bearing which holds the top of the quant.

- Ensure there are no obstructions to the brake wheel and tail wheel.

- Check that the return spring (rabbet) string is attached to the shoe. Adjust the twist peg to raise the shoe clear of the runner stone and set the rate of grist delivery to the stones. The third string is attached to a twist peg on the spout floor so that the miller can raise the shoe to shut down the mill temporarily. .

- Ensure the grain feed hole from the hopper is open to the required amount.

- Fill the hopper with grain. NB If using the bell alarm, press the leather strap against the side of the hopper while filling with grain.

- Ensure the shoe is filled with grain.

- Engage the stone nut and screw the quant bearing into the glut box until tight then unscrew one quarter to half a turn.

Spout Floor

- After the previous grind, the runner stone should have been raised four full turns of the horned nut on the tentering system to air and dispel heat. If not, raise the stone using the horned nut until the runner stone can be pushed round manually. Get the mill running and gradually lower the stone until the required grade of flour is achieved.

NB. Take care not to allow too much grain to clog up the runner stone.

High Salvington Mill has the unusual addition of a separate means of lifting the runner stone, which we refer to as the “clutch”. Should the stones become clogged with too much grain, we can lift the runner stone by pulling the clutch rope, which allows the runner stone to start turning again. By cutting off the flow of grain in the shoe and gradually lowering the stone, the blockage can be removed. It will then be necessary to re-adjust the flow rate into the eye of the runner stone, for the current wind conditions.

At no time should the runner stone touch the bed stone. There should always be grain between the stones. If there is insufficient grain and the stones rub together, there is a risk of fire.

Should the stones rub, the sound of grinding will become harsher and you will smell them.

- THE SENIOR MILLER MUST AUTHORISE THE RELEASE OF THE BRAKE.

THE MILLING PROCESS

Using the clutch rope, gently raise the runner stone until the stone is turning free, then release the clutch rope very slowly to allow the runner stone to commence milling. ( The horned nut is generally raised 4 complete turns after a session of grinding to allow air to flow between the stones )

- Allow an amount of meal through the stones as cleaning waste and discard it before collecting meal for bagging.

- The stone gap (or nip) will then need adjusting with the “horned nut” to obtain the fineness and quality of the meal required.

- Feel the meal occasionally as it descends the spout and make adjustments to the nip as required. This is a balance between the fineness of the flour and the ability of the mill to turn.

When Milling is complete.

- When milling is complete, the miller must ensure that the stones do not continue to revolve after the grain shoe is empty.

- Disengage the stone nut.

- All unused grain must be recovered from the hopper and shoe and placed in a sack for storage in a bin.

- The spout must be brushed out and left in a clean condition, the sweepings being discarded as waste.

- The runner stone must be lifted with 4 complete turns of the horned nut to allow air to circulate between the stones.

- Cover the hopper and eye of the stone with the cloth.