Practical Flour Milling - Fosters Mill, Swaffham Prior, 13 October 2023

Introduction & Learning Objectives

This course provides delegates with practical guidance on traditional flour milling using horizontal millstones, from purchasing grain to delivering flour to the customer. Delegates will learn about grain and how bakers use flour, milling flour, dressing flour, mixing flours, safe use of sack hoists, bagging up and weighing processes and factors around food hygiene.

The course will therefore involve both hands on practical experience and 'classroom based' learning.

Whilst the course will take place in a working windmill, the information will be equally relevant to those who work in water mills.

Learning Outcomes

- To understand how bakers use flour and therefore the qualities to look for when buying grain and milling flour.

- To understand the Law encompassed in the Bread & Flour Regulations 1998.

- To understand how to store and condition grain before milling.

- To obtain practical hands-on experience moving grain and flour around a mill using sack hoists.

- To obtain practical hands-on experience milling flour, dressing flour and mixing flour.

Buying & Conditioning Wheat

Buying Wheat

Whether you choose to buy grain directly from the farmer "off farm" or through a grain merchant, the grain needs to be of a particular quality and have certain properties to be suitable for milling.

If the flour is to be used for baking, the baker is looking for particular levels of protein and Hagberg (see below) depending on the product to be manufactured. Let's look at some terminology.

- Protein - a measure of the amount of protein in the wheat.

- A "Strong" flour will typically contain between 13% and 15% protein.

- A "Soft" flour will typically contain between 11% and 12% protein.

- A higher protein creates a stronger gluten in the dough.

- Biscuit flours have low protein.

- For bread flours, you are advised to ensure the protein is greater than 12%.

- Hagberg - a measure of the amount of sugar or starch in the grain.

- A high hagberg (more than 350) means the grain has a low content of sugar.

- A low hagberg (less than 250) means the grain has a high sugar content as the grain has turned its store of starch into sugar (i.e. the germination process). Grain with a hagberg of more than 350 or less than 250 should be avoided.

- Moisture - A measure of the amount of water in the grain.

- Grain should be purchased and stored with a moisture content of less than 14%, preferably around 12%.

- To mill, and achieve the greatest possible release (important in white flour production) and flaking of the bran, wheat should be around 16% moisture, done by adding water to the grain and leaving it for 12 hours to allow the wheat to absorb the moisture.

- Bushel Weight - a measure of the density of the grain.

- A high bushel weight indicates big, fat grains with lots of starch in them - good for white flour!

- A low bushel weight indicates small grains, lots of bran and low amounts of starch - not ideal for milling or white flour extraction.

- Aim to ensure the bushel weight is greater than 75.

Unless you have cleaning facilities in the mill, you re advised to purchase grain cleaned, preferably using a gravity table separator to ensure that dust and seeds (other than the wheat!) have been removed. Always ask for a lab analysis to provide information on the above measures.

Lifting & Moving Sacks

Introduction

Wheat fit for milling has to be cleaned to remove grit, dust, seeds and other 'foreign bodies'. This requires a cleaning process to be undertaken either at the farm or at the mill. Today most mills purchase wheat that has already been cleaned using a gravity table separation process which grades the grains, takes out the very small grains and other impurities and polishes the wheat ready for milling.

Wheat Delivery

Wheat is typically delivered in the following ways:

- 25kg paper sacks.

- 500kg or 1 tonne tote bags - polypropylene woven bags.

- Bulk delivery by truck - usually > 10 tonnes and < 30 tonnes.

Lifting Sacks

- Where possible, lifting sacks should be avoided, especially when lifting from floor height upwards. Try wherever possible to use a sack barrow to move sacks from place A to place B. When lifting is required, follow best practice manual handling techniques:

- Avoid bending your back - bend your legs and pick up the sack with both hands lifting to chest height.

- Carry over your shoulder - if you need to carry the sack for any distance, carry the sack over your shoulder with the weight distributed evenly on either side.

- Don't bend over when you put a sack down - to put down a sack, keep your back straight and bend your legs to lower the sack to the floor.

Elevators (not relevant at HSM)

Elevators should be kept clean to ensure that grain does not remain in the lifting buckets or elevator pit.

Elevator belting should be regularly inspected for wear and tear and bearings oiled.

Lifting flour and lifting grain requires different shaped buckets - ensure you are aware of which type of bucket is present in your mill!

Wind Milling Checklist

Introduction

The guidance notes below are designed as a checklist you need to follow before commencing milling and after completing a milling session. The notes have been prepared to apply to all windmills, so you need to review them against any specific procedures required at your mill and take account of the type of mill and if sail / sweep construction.

Before commencing milling:

- Check the weather forecast and look at the sky - what are the current meteorological conditions telling you?

- Carry out a visual inspection of the sails / sweeps looking for damage, in particular loose shutters / shutter cranks, breaks in the working uplongs, hemlaths or debris lodged in the sails - act on any problems identified before proceeding further.

- Check any winding gearing - is the mill facing into the wind, correct as required.

- Grease the neck bearing, tail bearing, wallower, lineshaft bearings, bearings along the upright shaft.

- Oil the foot bearings of the stone spindle (if required).

- Check the stone furniture is clean and the millstones are 2 turns (of the tentering screw) up.

- Check the flour spout is clean.

- Check the alarm bell is free and working.

- Check the magnet in the shoe to ensure it is free of metallic objects.

- Ensure the hopper is filled with wheat (watch that the wheat does not flood the stones, but ensure wheat is into the shoe).

- As you fill the hopper, do a visual check of the wheat for ergot grains / chaff/ seeds / bugs and any metal objects.

- If wheat needs to be moved around the mill in advance of milling use the sack hoist to carry out this activity now.

- Engage the stone nut and ensure any rigger or lift ring is free and out of the way.

- AGREE who is responsible for milling and allow that person to control operations from this point onwards.

- Ensure everyone present understands the emergency procedure for stopping the mill.

- Set the cloth using the agreed working procedures at the mill and remove the brake.

- Enjoy milling!

- Check the consistency of flour as required - be aware that as the stones warm up they may need additional tentering.

- Ensure the millstones do not run dry of wheat - make sure someone regularly checks the hopper.

- Keep a regular eye on the weather looking out for signs of changing weather / wind direction - act accordingly.

After milling:

- Apply the brake safely after / before removing the cloth / opening the shutters as is required based on your standard operating procedures.

- Lift the mill stones by 2 turns of the tentering screw.

- Disengage the stone nut and ensure it is secure in the "up" position (assuming the mill is under drift).

- In an emergency, when the brake wheel has stopped, insert a sprag of timber through the spokes of the wheel and a wedge and gradually allow the wheel to take up any slack so that the wheel is blocked off but you can drive the wedge out with ease.

- If you are not milling again during the rest of the week, clean the stone vat removing any flour that has collected and not fallen down the flour spout.

- Vacuum the whole area and once cooled, cover with any protection as required. ENSURE you allow the stones to cool BEFORE covering them up.

Water Milling Checklist

TBD.

Sack Hoist & Elevators

Sack Hoists

As with any lifting machinery, great care must be taken when operating a sack hoist.

The following notes are designed as a general guide, although you should review them in relation to your own mill to ensure that a proper plan is in place.

Operating a Sack Hoist

Where possible, position someone at the bottom and the top of the sack hoist to load and off-load sacks.

The person at the bottom of the sack hoist should control the sack until it passes through the first trapdoor and the doors have closed after it. From this point onwards, it is controlled by the person at the top of the sack hoist who controls the lifting process until the sack is up to the desired level in the mill and the doors beneath are shut to prevent it falling.

Some pointers:

- Keep out of the path of the sack - ensure you do not stand under a sack at any time or in the path of a sack coming up or down the mill.

- Keep sack trap doors locked when not in use - ensure that sack trap doors are secured and locked to prevent tripping on them or falling between floors in the event of a door being left open.

- Keep visitors away from the sack hoist when in use - it is often good practice to close the mill if possible when the sack hoist is in use or lift wheat / flour when the mill is closed to visitors.

Testing of Chains

The Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) require that lifting equipment must be fit for purpose and tested annually by a competent person. To comply, the sack hoist must be tested each year and a certificate retained for inspection to confirm the chain and bollard are safe and fit for purpose.

Elevators (Not relevant at HSM)

Elevators should be kept clean to ensure that grain does not remain in the lifting buckets or elevator pit.

Elevator belting should be regularly inspected for wear and tear and bearings oiled.

Lifting flour and lifting grain requires different shaped buckets - ensure you are ware of which types of bucket are present in your mill!

Dressing Flour

Introduction

There are two main types of flour dressing machines found in traditional mills, "Bolting Machines" or "Centrifugal Machines". Bolting machines are also referred to as "Reel Bolting Machines" or "Wire Machines". The name Bolting comes from the name of the cloth which was used to sieve the meal - the process which these machines carry out today.

Bolting Machine

Here the meal is passed through a cylinder which is coated in either bolting cloth or more normally stainless steel mesh. The meal is agitated by wooden beaters which spin or brushes which force the meal against the mesh or cloth to sift it; the fine particles passing through (white flour), the larger particles remaining in the cylinder and passing out of the end. Most Bolting Machines have two or three grades of mesh on the same cylinder allowing the miller to sieve out white, "brown" meal containing more endosperm, middlings - a coarse meal with a texture like sand with the bran passing out of the end.

Centrifugal Machines

These machines have a rotating drum covered in bolting cloth and beaters or brushes within the drum which agitate the flour. They are more efficient than Bolting Machines and able to process larger quantities of flour more quickly.

Some pointers:

- Meal should be allowed to cool before dressing - warm meal has a tendency to stick in most dressing machinery leading to clogging of the machine.

- If not in regular use, clean the machine fully after use - dressing machines are magnets for mill moth as there are plenty of places for flour to collect and remain undisturbed.

- Clean out the dresser every three months if in regular use - good housekeeping!

Milling Flour

Millstones

There are three main types of mill stone found in UK mills - peak stones (a soft stone suitable for milling wholemeal flours), French Burr stones (hard stones suitable for milling all flours, in particular meal to be dressed for white flour) and composite stones (artificial stones, usually suitable for all types of flour production).

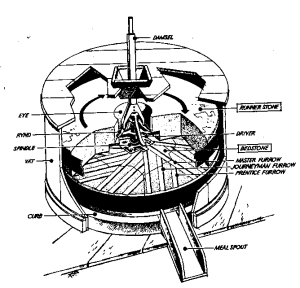

Exploded Diagram

This diagram shows a set of millstones and below how the grain is crushed when the runner stone turns on top of the bed stone.

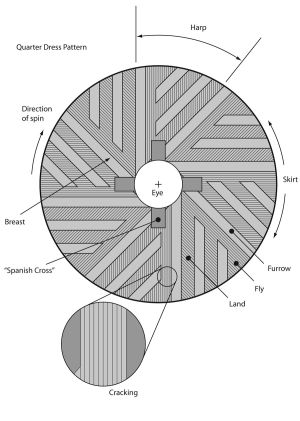

Dressing Pattern

This illustration shows the Quarter Dress Pattern which is typically found in the UK.

Millstones require dressing when the surface becomes uneven through use, when the land surface becomes polished through use and when the Furrows cease to be deep enough. It is not possible to predict how many tonnes of wheat a set of stones will grind before requiring dressing - when they are blunt the meal becomes hotter and it is more difficult to maintain a fine grist without greatly reducing the amount of wheat passing through the stones.

Tips when operating the millstones:

- One person should be in charge of milling.

- It is not advisable to leave the mill running unattended.

Before commencing milling

- If the mill has not been used within the last month, strip down stone furniture and open up the stones - clean with a stiff brush and vacuum.

- If the mill is used regularly, clean down every three months.

- Check and grease all bearings before starting up.

- Check the alarm bell is free and working.

- Check the flour spout is clean.

- Ensure there s a well understood procedure for stopping the mill in an emergency.